-

Phone

+86-13425055322 -

Email

sales@bohoele.com -

Email

celia@bohoele.com

Choosing the Right Wire Crimping Tools for Your Projects

Wire harnesses vary from different working systems, but the process generally requires electrical wires, connectors, wire terminals, and other tools. Wire crimping is one of the essential steps in wire harnesses. It is a process of joining wires to wires or wires to terminals to produce an electrical circuit and deliver the electricity to other equipment.

To crimp wires perfectly, you need to choose the right tools for different terminals. And you’ll learn how to choose the correct tools for good wire crimping in this post.

What is a Wire Crimping Tool?

Wire crimping tool is often used in electrical works to make a joint between two wires or attach the wire to other connectors. They commonly come in different shapes and sizes, but the basic function of these crimping tools is to create a reliable connection. Instead of soldering, electrical crimps make the joint mechanically stronger and more flexible. So, how to choose the right crimping tool for your electrical work? Read on the article.

How to Choose the Best Wire Crimping Tool?

An electrician professional needs the right tool to get their work well done. A wrong tool may make you frustrated as your work needs to be done again later. A DIYer also needs a good wire crimping tool to create an electrical system.

There are different types of wire crimping tools on the market, and here we’ll introduce two mainly used crimping tools. They may have slight differences, and here we’ll dive into the detailed information about them. These two types of wire crimping tools are classified based on the terminal types. So, before knowing the types of wire crimping tools, you need to understand different types of terminals.

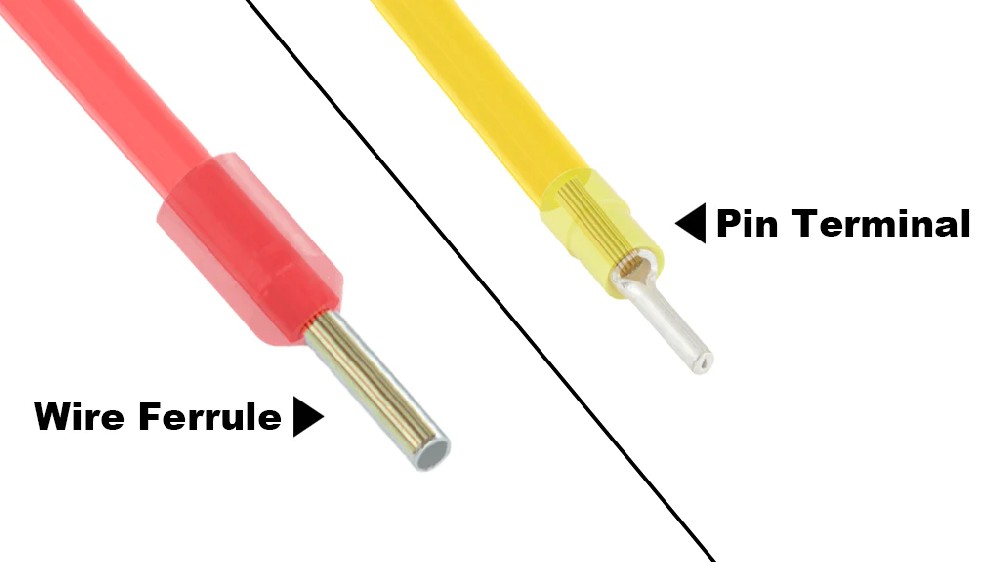

Wire terminals are very common in electrical applications, and wire ferrules (also known as bootlace terminals) are often used in Europe. There are many terminal designs including electrical ring terminals, spade terminals, hook terminals, butt terminals, bullet terminals, pin terminals, and so on.

Pin terminals are very similar to wire ferrules, so what’s the difference between them? Wire terminals are crimped on the insulation and the central area has a diameter smaller than the wire. In comparison, wire ferrules are crimped on the end of the terminal, and the central area has a diameter larger than the wire. Pin terminals are suitable for some terminal block applications, and wire ferrules can be more suitable for industrial applications.

A terminal crimper is very functional as it can crimp many kinds of wire terminals, including ring, spade, and butt terminals. It is often labelled with AWG on the body or grip, allowing you to crimp terminals with different AWGs.

Tips: When selecting the crimping tool, consider the wire size. What is AWG? The full name of AWG is American Wire Gauge. It was first introduced in 1857 to unify the measurement of the cable wire. In general, the larger the number of AWG, the smaller the wire diameter. For example, 16 AWG wire is thinner than 10 AWG wire.